As I continue to hear about new organizations reimagining how to run a sustainable business and implement a sustainable supply chain, I wonder, isn’t this just adding more industry on top of industry? Are we just creating more problems to solve?

Take the fashion industry for example. It’s traditionally one of the most harmful industries from an environmental and societal perspective, and there is a rise in sustainable fashion (made-to-order, alternative materials, alternative manufacturing, ethical labor, etc.). These businesses are still producing a net addition of clothing into circulation, possibly even worsening the issue if larger fashion retailers are unable to sell their pre-made stock! Shouldn’t we then focus our efforts on making what we currently have, better? Can these new businesses help to encourage, if not force, larger organizations to look within? Isn’t that where the impact will be noticed more?

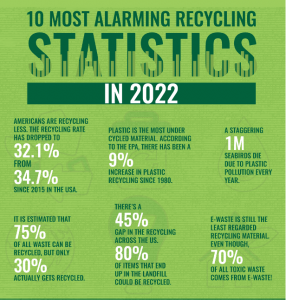

These questions and thoughts took me back to a very basic and fundamental concept: Recycling. When we think about recycling we likely think of the recycling logo but what we might miss, and what I missed, is the not-so-hidden messaging. I rarely noticed, or registered, the order of the words in the standard “Recycling” logo but now appreciate that it is a guide for the order of operations of impact from biggest to smallest: Reduce, Re-use, Recycle. Unfortunately, the order is in reverse for simplicity of implementation: recycling programs are theoretically easy to implement versus undergoing reduction efforts, but there are loads of myths about recycling (see below for some statistics). However, this same, simplistic logic can be applied to supply chain strategies to deliver upon sustainability goals/objectives and assisting in identifying the most impactful areas to target.

With “Reduce” being the first, and most effective, option, supply chains are looking towards creative solutions to reduce carbon footprints, for example. Organizations are looking to reduce the energy consumption in manufacturing, reduce waste streams, reduce dependencies on unsustainable inputs, and more. Reduction has been identified as the highest impact because it happens upstream. Back to my fashion example, can we reduce the overall production of these goods to more equally match supply and demand thus reducing energy and waste?

With “Reduce” being the first, and most effective, option, supply chains are looking towards creative solutions to reduce carbon footprints, for example. Organizations are looking to reduce the energy consumption in manufacturing, reduce waste streams, reduce dependencies on unsustainable inputs, and more. Reduction has been identified as the highest impact because it happens upstream. Back to my fashion example, can we reduce the overall production of these goods to more equally match supply and demand thus reducing energy and waste?

Re-use follows reduction and aims to pick up where reduction left off. If you cannot further reduce, can you find an alternative outlet? In manufacturing, can your waste/excess go back into the production process? Can that material be utilized as an input into a different process in a different industry? Giving products multiple lives is part of re-using them along with designing products to last longer (though I’d argue that’s part of reduction efforts upstream… if you make a product last longer, maybe you produce less overall?). Re-use introduces the concept of a circular economy which I will address in a future post…stay tuned!

The last resort is recycling. If you think about it, recycling is similar to the last link in a supply chain (e.g. last mile logistics). You can only optimize so much at the end of the chain before you naturally start creeping back upstream (like I just did in the last section without even trying!) into the chain to stop problems before they even start. In practice, this can be seen when working with planning teams placing inventory in the right places before dealing with last mile logistics. If inventory is located at optimal locations for distribution, you would fight a lot less about the cost of that last mile delivery.

While I still don’t have answers to lots of my questions, none of this says to stop recycling and only focus on reducing and re-using, but, it is worth nothing that reduction is the first line of defense that presents the largest opportunities for improvement. Translating that to supply chain strategy—don’t stop doing what you are already doing, but be open about identifying bigger wins even if they take longer to realize. Any time you can tackle the root cause of an issue, you will likely reap other benefits (like problems downstream solving themselves, or never arising in the first place) allowing you to concentrate on more value-add activities.

Source: https://hummingbirdinternational.net/infographic-recycling-statistics-2022

—Kira Bilecky, St. Onge Company