Strengthening your supply chain one link at a time.

Strengthening your supply chain one link at a time.

Staging product near the outbound dock is one of the most common methods of preparing a shipment before loading. When the outbound trailer is not yet available, staging serves as a buffer, allowing picking and packing to be completed in advance of loading.

Outbound staging requires space, yet, many distribution centers fail to leverage their warehouse management system (WMS) to manage this space. The same functional principles that facilitate put-away, inventory control, picking, and packing can facilitate staging, preparing, retrieving, and loading product onto a trailer.

![]()

Your outbound dock is essentially an additional storage area within your warehouse – tracking cartons and pallets by shipment versus tracking units by item. Expect your WMS to support outbound staging as a comprehensive process. Doing so will reduce your teammates’ manual efforts and free their talents to address other aspects of your operation. Below are important concepts to consider when preparing a less-than-truckload (LTL) or multi-stop outbound load.

STAGING

The goal is not to fit all product for a shipment within a single, large staging location. Instead, I recommend delineating the outbound staging area into several small locations. More discrete staging locations will better control inventory and activity within this area and improve overall space utilization.

While a shipment may require multiple staging locations, each staging location should support the product for only one shipment. By not mixing shipments within a staging location, destaging product will ultimately be more efficient.

There are three methods to manage outbound staging locations:

Once a staging location has been selected for a load, subsequent product for that same load will follow-the-leader to the same staging location. Once the teammate identifies a given staging location as full, an empty staging location is identified and the process continues.

PREPARING

Aggregation by pallets by shipment in a staging location will help identify opportunities to merge two partial pallets into a single, larger pallet. These are opportunities to improve load stability and trailer utilization.

If not accommodated by other methods earlier in the outbound process flow, the staging area can prove a control point to prepare each pallet:

Each of the above can be automatically triggered through the WMS simply by scanning each pallet’s unique license plate.

To help manage your overall outbound process, consider the WMS’s capability to provide both a “leading” and “trailing” status (by load, shipment, order, or line). For example, if 90 percent of an order’s product has been staged (the leading status), but 10 percent has not yet been picked (trailing status), your ability to review and resolve such exceptions is greatly improved.

RETRIEVING

The best practice for retrieving staged product is for the teammate to initiate the process and for the WMS to direct and validate the process. In other words, the teammate identifies the outbound load. Knowing the shipments and staging locations entailed, the WMS will direct the teammate accordingly.

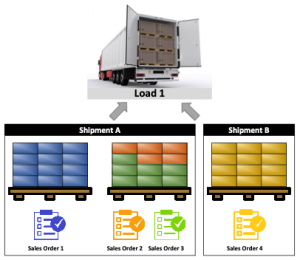

If the outbound load is a milk-run or other multi-stop delivery, sequenced loading is essential. Although delivery sequence is not applicable when loading a trailer for an LTL carrier, loading by shipment will aid processing within an LTL terminal.

If product for a load has been staged in multiple locations, the WMS will direct the teammate to each location considering the defined travel path (see previous entry regarding location sequencing).

As each pallet is retrieved from a staging location, the WMS can display to the teammate a count-down of pallets remaining in that location. Ultimately, the WMS will require the teammate to confirm the location is empty as the last pallet is retrieved (see previous entry regarding similar inventory control techniques).

Depending on your material handling equipment and WMS configuration, multiple pallets can be retrieved before loading the pallets onto the outbound trailer.

LOADING

As pallets are loaded, configure your WMS to require the destination to be verified. Most commonly, the destination is a door number. In this situation, the verification barcode should represent a hidden alias specific to the door – not simply DOOR12, which can be easily key-entered.

Validation not only provides assurance that product is loaded onto the correct trailer, but it also provides an additional transaction history record. For example, retrieving product from staging provides one record; loading product into the outbound trailer generates a separate record. These unique records will not only provide traceability but also delineate a teammate’s time, which is essential to transform “activity” reporting in to “productivity” reporting.

Similar to the trailing and leading status described above, the WMS should provide a warning if any product has not been loaded before the trailer is closed. If a pallet is still in outbound staging, for example, the specific staging location will help your team quickly locate and resolve the exception.

— Kail Plankey, St. Onge Company