Strengthening your supply chain one link at a time.

Strengthening your supply chain one link at a time.

Warehouses and Distribution Centers (DCs) are notorious for overlooking a key area in logistics and supply chain management – the yard. The yard is where trailers are staged, loaded, and unloaded. Deploying a yard management system (YMS) supports managing the flow of trucks, trailers, and inventory in the yard. A YMS gives visibility and control over the movement of yard operations contributing to the planning, scheduling, inspection, and movement of trucks, trailers, and containers.

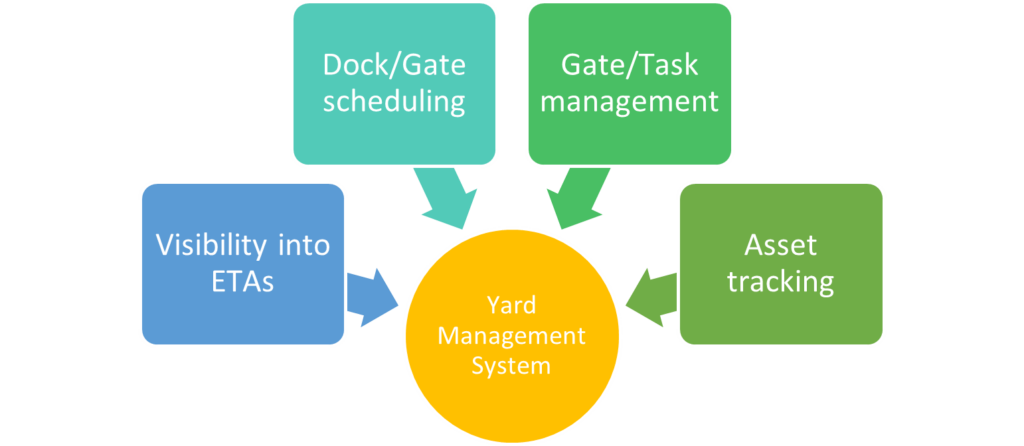

Key features of a YMS consist of real-time visibility into driver estimating arrival times (ETAs), tracking the location and status of trailers and containers, ensuring dock/gate optimization, automating check-in and check-out processes, and overseeing yard operations (e.g. trailer moves, inventory counts, etc.)

What are the key benefits of a YMS?

Immediate benefits of implementing a YMS include reducing manual processes, minimizing errors, better decision-making, decreasing idle time, strengthening customer relationships, and maintaining compliance with regulations and security protocols. It’s common for some clients to use spreadsheets for appointment scheduling, yard checks, and gate management. A YMS reduces human error and enables carriers and dock teammates to communicate more efficiently. An integrated YMS minimizes idle time for trucks/equipment and helps to reduce congestion. To prevent theft and unauthorized access, a YMS uses technology like radio frequency identification (RFID), GPS tracking, and barcode scanning to monitor the location and status of trucks and trailers in the yard.

What’s the difference between a YMS, WMS, and TMS?

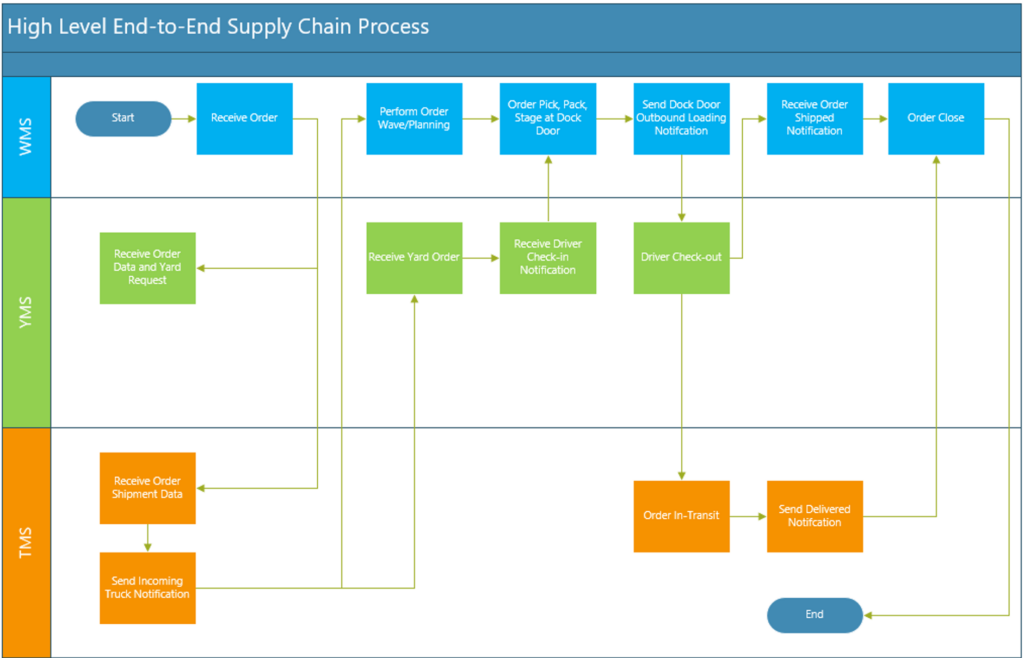

Historically, YMS has not received as much attention as warehouse management systems (WMSs) and transportation management systems (TMSs). WMS and TMS have been viewed as the core processes for supply chain execution. YMS strengthens and bridges the gap between WMS and TMS by providing support for yard operations. A WMS manages the movement, storage, and tracking of goods within a warehouse. A TMS provides route optimization, carrier selection, and freight auditing for transportation and logistics operations. A YMS module can be integrated as an extension of the WMS or TMS. Supply chain managers have full visibility into the movement of goods at each stage when YMS, WMS, and TMS are integrated. For example, please see the high-level end-to-end order fulfillment swim lane diagram below:

Who benefits from YMS deployments?

It’s not uncommon for yard management activities to be managed manually via whiteboards and spreadsheets. Yard management is often viewed as a black hole. Anyone who has experienced the daunting task of looking for inventory in the yard that has not been received yet into the WMS can benefit from a YMS, or if a product is lost in a trailer in the yard. Additional yard challenges include:

If you are seeking an automated solution for dock management/scheduling, reducing paperwork and phone call volume, performing regular audits, and tracking the location of assets – it may be the right time to focus on yard management. A YMS contributes to a more sustainable supply chain by streamlining yard operations. Since a YMS can integrate with other systems like WMS and TMS, this level of transparency can help avoid expensive disruptions, such as missing delivery windows due to yard delays.

—Ashley Rhodes, St. Onge Company