Strengthening your supply chain one link at a time.

Strengthening your supply chain one link at a time.

Warehouse slotting organizes warehouse inventory to make picking, putaway, and replenishment easier and faster. To implement slotting, warehouse leaders use different criteria to organize warehouses in the most effective way to increase picking efficiency and improve customer satisfaction. Some leaders may focus on dimensions, weight, or sales forecasts to optimize their warehouse. While other leaders may choose to focus on how often a product is sold. There are several factors to consider before determining the most efficient slotting strategy. It is recommended to begin by collecting the following data:

Once all data is collected, you can start evaluating different slotting strategies. Slotting improves picking performance, optimizes warehouse pick line space, and reduces inventory management and warehousing costs.

There are three different types of slotting: static, random, and dynamic.

Static or fixed slotting assigns a permanent location for each product. Generally, static slotting is for warehouses with few high turnover products.

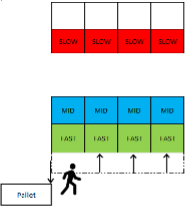

In random slotting, SKUs are stored anywhere space is available. The same product can be picked from a different location to reduce time for replenishment. However, random slotting can cause increased walk time to retrieve the product (see Image 1 below) and reduce the visibility of stock.

Image 1

On the other hand, dynamic slotting is a strategy that allows product locations to change (see Image 2 below). For instance, if there are not enough locations available to accommodate a product or when high-demand SKU requirement exceed space in the existing location, a temporary location can be assigned by the warehouse management system (WMS) to meet the increased demand. A WMS gives flexible slotting capabilities to reduce picking and replenishment costs. When the pick is complete and the inventory is empty, the product location will be available for a different SKU.

Image2

While most organizations have already implemented some form of warehouse organization, slotting allows you to focus on the overall layout of products and SKUs that require special treatment to improve inventory management, product picking, and efficiency. A WMS can provide predictive data to forecast material flow based on pick queue priority. With a WMS integration, pickers can be directed to product locations via an optimized picking route. The WMS would be able to keep track of demand in real-time and provide a slotting strategy for “fast-mover” SKUs to be placed nearest to the shipping dock for example.

Efficient slotting can save organizations up to 20% in labor costs and enable leaders to make timely, intelligent decisions to meet customer demand. Manually slotting is possible but also time-consuming. Integrating a WMS with a slotting functionality allows products to be picked and delivered faster. Warehouse inventory slotting constantly updated to maintain effectiveness as the velocity of SKUs varies over time.

St. Onge provides consulting services to streamline your workflow and maximize available storage space. Slotting optimization is just one the tools and approaches available to enhance your warehouse’s efficiency.

—Ashley Rhodes, St. Onge Company