Strengthening your supply chain one link at a time.

Strengthening your supply chain one link at a time.

The phrase “network optimization” has several different definitions depending on the audience and need.

At the highest and simplest level, a supply chain network optimization study is designed to answer the following questions:

That may appear to be a fairly straightforward request until we consider a relatively small business network. If a company with 2 distribution centers shipping 300 items to 10,000 customers wanted to optimize their network from among 20 potential distribution centers and 10 different suppliers, we are asking a network model to consider 600,000,000 combinations. Given current technology, a “simple” network could take several days of computer processing time to solve. In order to address this level of complexity, optimization efforts are often aggregated; however, with each level of aggregation detail is lost.

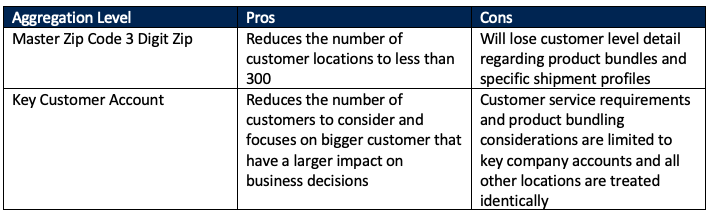

Customer aggregation:

Product aggregation:

With every level of aggregation, business detail is lost. It is important that a network optimization effort begins with an aggregation discussion, because within each effort, there are 2 categories of questions:

What should be done can often be clear; however, what it is worth becomes more complicated. For example, if a business currently ships 1 product line from a single location, and 4 other product lines from 3 locations with significant customer overlap, a network study may help answer the question, “Should the business combine all 5 product lines to ship from 3 locations?” The answer, “Yes, probably.” However, what is it worth becomes increasingly complicated. When the aggregation pros and cons are considered, we realize too much detail is lost at each level of aggregation to quantify the savings associated with such a move. Since, not all customers in a geographic region take every product in a product line, a study should be broken down into manageable efforts.

In this example, a study should first determine how many sites should warehouse each product based on customer and product similarities, such as service requirements, inventory carrying costs, product velocity, etc. Once it is determined how many warehouses should store each product, a new level of aggregation to include number of source warehouses per “like items” to “like customers” could be considered. Breaking a study into multiple steps allow the sourcing decisions to be detailed enough to include cost considerations and aggregated enough to provide guidance in a reasonable amount of time and at a reasonable cost.

Since nearly every network optimization effort will require some level of aggregation, it is critical to determine the scope of an effort collaboratively between the modeler and the business stakeholders thoroughly and early in an engagement to ensure an actionable result. As the Rolling Stones said, “You can’t always get what you want, but if you try sometime, you’ll find, you get what you need.”

—Jeff Schmidtke, St. Onge Company