One hot topic in sustainability is around the circular economy which in theory sounds great, but from a supply chain execution standpoint can be crippling to an existing business.

The Ellen MacArthur Foundation explains this concept very well in my opinion: “In our current economy, we take materials from the Earth, make products from them, and eventually throw them away as waste – the process is linear. In a circular economy, by contrast, we stop waste being produced in the first place.” This feels a lot like addressing the root cause of an issue, stopping a problem before it even starts. This philosophy is absolutely applicable in the supply chain field as I’ve mentioned in several other blog posts about supply chain and sustainability – the further upstream you can address an issue, the better (though it applies to general supply chain as well not just sustainability*).

So simply put, yet so difficult in practice to truly embrace what it means to achieve circularity and even harder to execute. From a supply chain standpoint, there are several implications to your business should you embark on the journey towards circularity, but the earlier in the process you start, the better. The three principles that drive the circular economy are:

- Removing waste and pollution

- Keeping materials and products in use for as long as possible without sacrificing their quality

- Returning materials to nature without a negative impact

If you read my previous blog post on the Recycling philosophy, this should sound pretty familiar and completely aligned with Reduce, Re-use, and Recycle. When we think about building a new supply chain, it is easier to build it with these tenets in mind, but redesigning an existing supply chain requires more thoughtful planning in order to not be debilitating or disruptive to the business. Many of our supply chains have been artfully designed and implemented with the traditional linear approach and further optimized with this in mind.

Moving to a circular model will require us all to rethink how we can transition these supply chains, not only in early design phases to eliminate waste but also understanding, possibly creating, a new reverse logistics or aftermarket supply chain network. While organizations are trying to offer easy solutions for waste or disposal, many are realizing that this puts a trust and burden upon everyday consumers. Instead, many organizations are taking this a step further and taking more control of their designs and products through their entire lifecycle, including disposal and end of life. This means they are finding ways that remove the burden from consumers and are accepting the responsibility themselves since they know and trust their own capabilities.

This is an entirely new segment of the industry that has not been fully flushed out yet, It is far more fragmented than the logistics from warehouse to consumer or even retail to consumer. There are so many logistics carriers that are focusing on getting the right product to the right consumer at the right time that allows companies to shop around, benefit from general economies of scale (pushing or sharing volume with all the other businesses sending product in that direction), and leverage best practices of a mature service offering.

Moving in reverse, organizations need to account for different solutions as the options are less developed and, as the origination point is with an individual instead of a warehouse, personal preferences and convenience start factoring in. There are several considerations when addressing the reverse chain, and many are intertwined with one another:

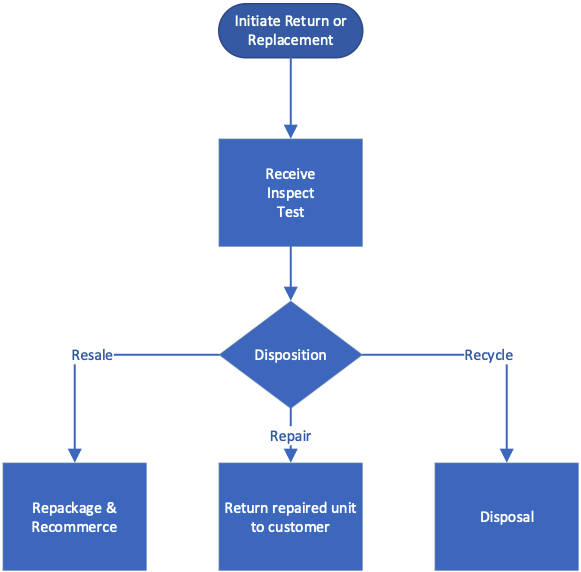

- Returns – while the most effective method is to not have a return to begin with, every organization should develop a process to best manage these, including shipping options, receiving and inspecting guidelines and any testing procedures. This is the foundation for determining the next step in the product’s lifecycle

- Reselling – since many products are returned for subjective reasons, there is still opportunity to give products a second life, helping delay, possibly avoid, the creation of waste.

- Repairs – after evaluation of a product, is it able to be quickly restored to its original condition and returned to the original customer?

- Replacements & Exchanges – though this option introduces a new outbound product (for example, a different size, color, etc.), there is still a returned item that needs to be addressed

- Recycling & Disposal – for whatever reason if a product is deemed unsalvageable, the product needs to be handled in an environmentally conscientious way by the organization

Organizations today are earning customer trust by providing transparency around their attempts at being more circular. Some address their usage of certain raw materials, some explain the durability and longevity of their products, others share their reverse logistics and disposition plans, but very few do all the above. How will your organization take on this challenge?

*Side note: At St. Onge, this is a major reason we designed supply chain assessments to do exactly that: look across the entire supply or value chain and identify the areas that will best achieve an organization’s desired result, whether that be minimizing cost, maximizing throughput, maximizing revenue, increasing efficiency, etc.

—Kira Bilecky, St. Onge Company