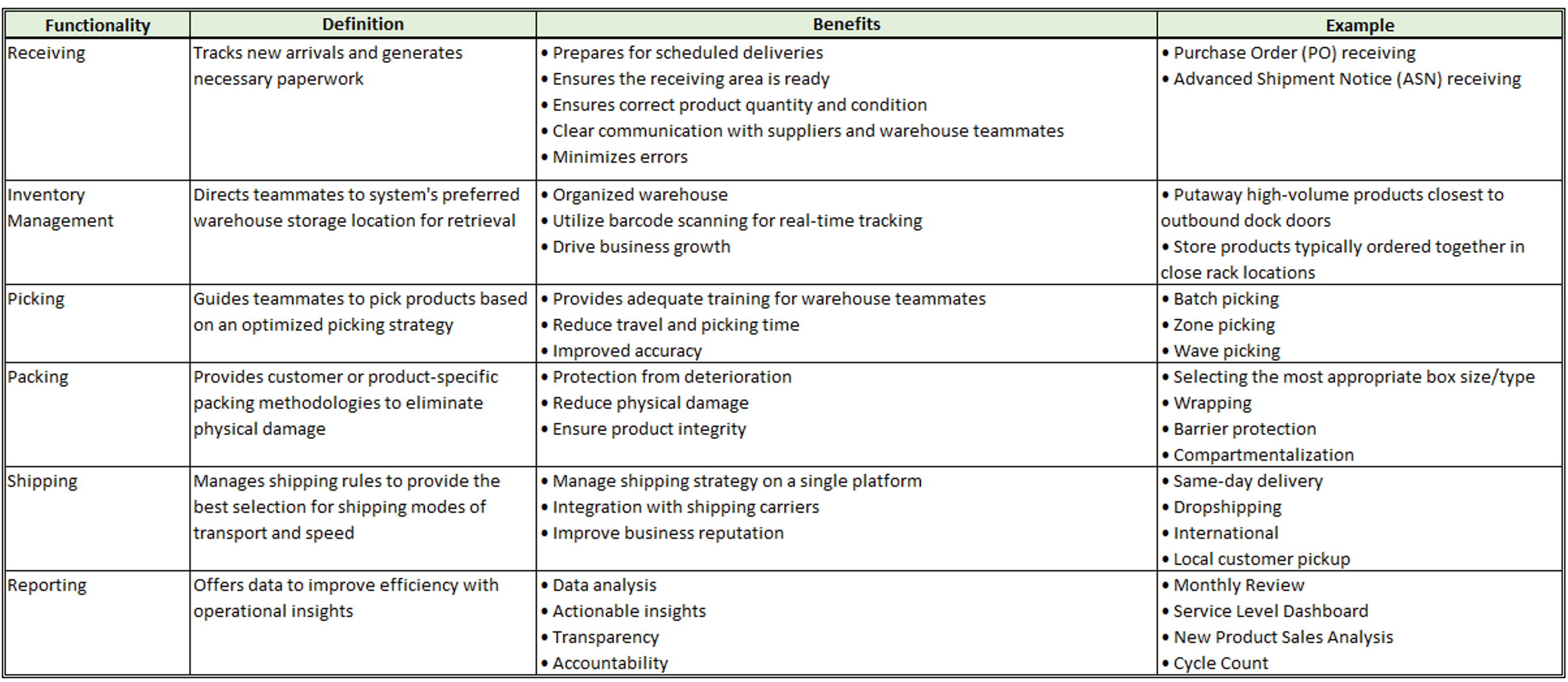

Selecting a warehouse management system (WMS) not only depends on your operational complexity but also on your budget. As a small business owner, your organizational goals may only include core WMS functionality and cost. For a WMS. a small business is typically defined as a single warehouse with fewer than 15 users. Fast cost recovery can be achieved within 7 to 10 months, thanks to more efficient operations and labor savings. Small business owners should beware of hidden costs when selecting a WMS that matches their requirements. Hidden costs can include system integration, customizations, training, and post-implementation support. With this, it’s best to start by identifying and documenting core process requirements. Core processes include receiving, inventory management (putaway and storage), picking, packing, shipping, and basic reporting. Prioritizing real-time inventory tracking, ease of use, and cost effectiveness allows small businesses to focus on a high return on investment (ROI). Here is a review of core functionalities and how they can benefit your business:

Once your core processes have been identified, make a list of potential unknown costs you may encounter throughout the duration of your system’s implementation. Hidden costs associated with integrations can include infrastructure upgrades, IT support and maintenance, and staff training. Reliable internet connectivity is crucial for cloud-based solutions. Network infrastructure upgrades may be necessary to reduce latency and downtime. Also, consider if the pricing structure is based on order volume or number of users – this way, you can have a better handle on scaling your business for future growth. Customizations can be very expensive, depending on whether they are simple user interface modifications or creating a new customized module. Costs associated with resources such as project managers, developers, or other specialists can drive additional costs as well. For instance, a simple report or interface modifications can range from $1,500 to $8,000. However, complex custom modules can range from $50,000 to $200,000 per module. Also, initial training costs can range from $1,000 to $5,000; however, ongoing training can lead to recurring costs if you experience high turnover or significant system changes. To fully understand cost estimates, define requirements, assess existing integrations, and contact a consultant or WMS provider to understand specific cost structures.

Preparing for a WMS to reduce inventory inaccuracies, picking errors, or delayed order processing, business owners can leverage the following best practices:

- Organize your warehouse by keeping the warehouse clean, using clear signage, efficient rack or bin locations, and storing frequently purchased items in close proximity for faster picking and replenishment. Reconsider your warehouse layout to optimize storage space and minimize travel time.

- Adhere to proper labeling throughout your warehouse (e.g., rack labels, floor labels, warehouse magnets, etc.) to provide real-tracking capabilities and improve operational efficiency and visibility. Easy-to-read labels can also improve safety and prevent errors when picking and packing.

- Standardize and document your current processes for rule setting and designing the best workflows within your WMS. Get insight from teammates on the front line who perform specific tasks daily, which can pinpoint bottlenecks or help identify activities that may cause muscle strain.

The result of implementing a WMS can have a significantly positive impact on productivity, operational efficiency, and customer satisfaction. An intuitive and easy to learn WMS will reduce the staff’s learning curve and increase confidence to better handle their responsibilities. Small businesses can transform their business performance by adopting a WMS that meets their requirements and budget needs. Reach out to St. Onge consultants to help you navigate the process of selecting the right WMS for your business.

—Ashley Rhodes, St. Onge Company